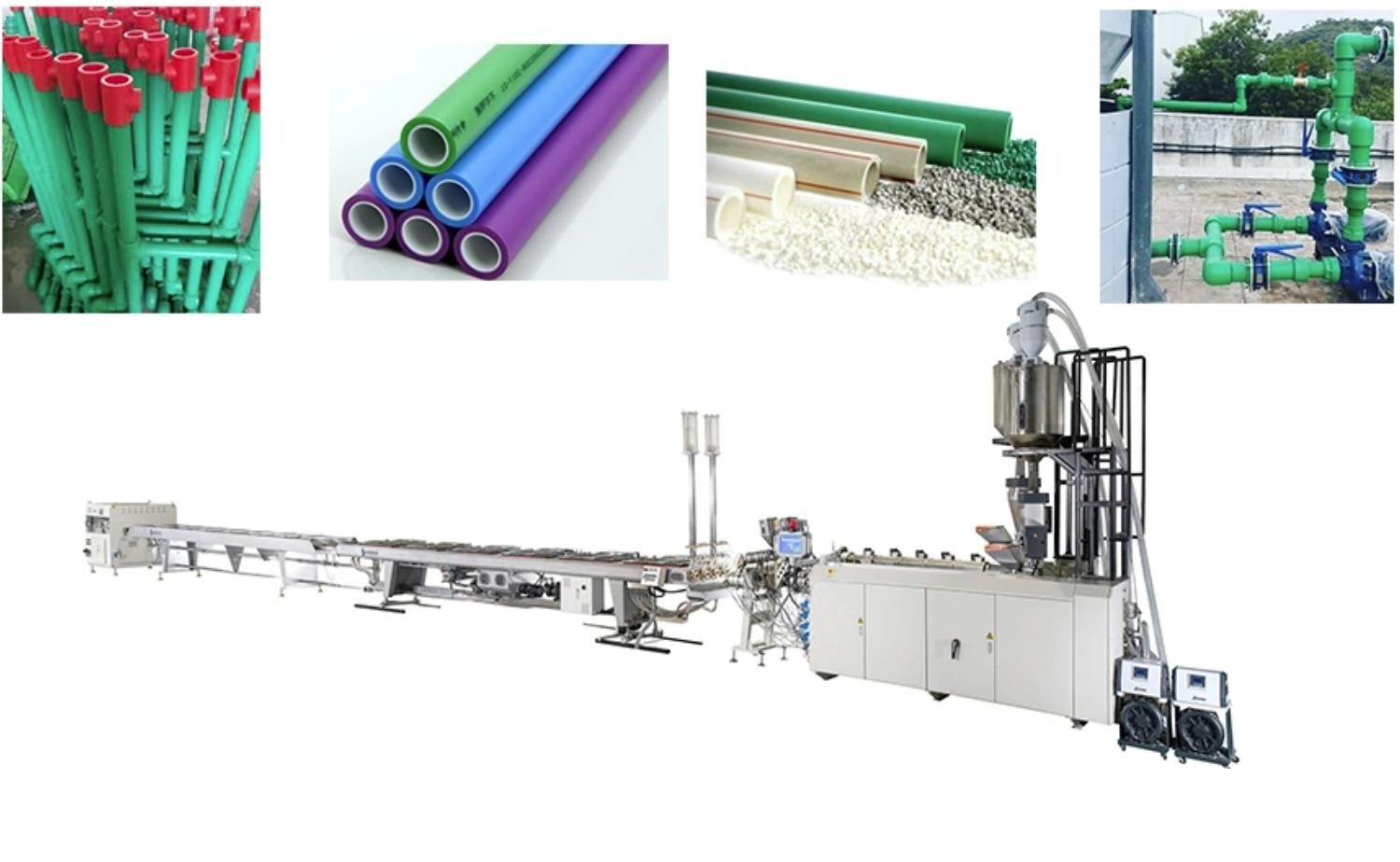

Layout of PPR pipe extrusion line:

PPR granules → vacuum feeder → hopper dryer → single screw extruder → marking line co-extruder → mold and calibrator → vacuum calibration tank → cooling tank →printer → haul off machine →cutting machine → stacker

Technical Characteristics

Capacity: new design high-speed single screw extruder, suitable to process PE / PPR resin with high capacity, 20-63 mm pipe can produce with double-outlet type, which can produce two pipes at one time with one die. 20 mm pipe can stably run at 25 m / min.

Diameter: from 16 to 2000 mm for PE pipe, 16-160 mm for PPR pipe

Adopt reasonable design, absorbing safe producing technology, acquiring CE & ISO certificate.

Use world-famous brand electric parts, such as SIEMENS, SCHNEIDER, ABB etc.

Technical Parameters:

Machine | Pipe | Vacuum Calibration Tank | Spray Cooling Tank | Haul-off unit | Cutter | ||||

Vacuum pump | Water | Length | Water pump | Length | caterpillar | Motor | Cutting type | ||

PPR-63 | φ16mm-φ63mm | 3kw*2 | 3kw*2 | 6000mm | 3kw*1 | 6000mm | 2 | 1.5kw*2 | No dust cutter |

PPR-110 | φ40mm-φ110mm | 4kw*2 | 3kw*2 | 6000mm | 3kw*1 | 6000mm | 2 | 3kw | No dust cutter |

PPR-160 | φ63mm-φ110mm | 4kw*2 | 4kw*2 | 6000mm | 4kw*1 | 6000mm | 3 | 1.1*3 | No dust cutter |

【 Go Back 】 | 【 Close this window 】